Many NC machine tools are currently being introduced at the production of mechanical parts.Above all, NC lathes and machineing centers are typical of NC machine tools.These are tools for making things.In order to perform "manufacturing" that satisfies the purpose of accuracy and efficiency, it is necessary to fully understand its characteristics and work.In this series, we will explain the basic knowledge of NC six times.This time, which is the first time, I will explain the definition of NC and control methods, entitled "What is NC?"

Lottery

1st: What is NC?

1.NC definition

NC was around 1950, American John T.It is said that Parsons devised.When producing the rotating wings of the helicopter, we have developed an NC milling board to efficiently and accurately producing a winged inspection gauge.Currently, many machine tools use NC technology and are indispensable for manufacturing.

NC is an abbreviation of the Numerical Control (numerical control).JIS is defined as "control of tool routes for work and processing necessary for processing with corresponding numerical information."In other words, it means "automatically moves machine tools by numerical values and symbols."

A controller that gives a command to a machine tool is called an NC device.With the conventional NC device, ...

>>第1回 第1章の続きを読む(PDFダウンロード)

2.NC control method

NC machine tools are composed of NC equipment and machine tools, as shown in Fig. 2.The servo mechanism is a mechanism that runs a knife stand or table of a machine tool by directing from an NC device.If you compare it in humans, it plays the role of limbs, and the NC device that issues the command is the brain.

図2:NC工作機械のしくみThe control method of the typical servo mechanism used in various NC machine tools is as follows.

...

>>第1回 第2章の続きを読む(PDFダウンロード)

3.Utilization of NC

In Japan during the high -growth period, the product life cycle was longer than the present, and the production form was "small variety of production".It is a way to make a lot of the same thing and sell it cheaply.For products with a large quantity, special machine tools that specialize in planar processing and hole processing were used.In addition, for products that are not completed with one dedicated machine tool, transfamachine, which is connected to a dedicated machine tool in order of processing, was used.

時代が進むにつれて、消費者ニーズの多様化や市場の変化などにより、製品ライフサイクルは以前よりも短くなりました。それに伴い、...

>>第1回 第3章の続きを読む(PDFダウンロード)

2nd: Types and features of NC machine tools

Last time, I explained the definition of NC and control methods.This time, I will explain the type and characteristics of NC machine tools.There are many types of NC machine tools according to processed objects, processing methods, and processing accuracy.The features are explained in comparison with general -purpose machine tools.In addition, we will take up the types of NC machine tools and the typical NC lathes and machining centers, and explain the composition.

1.Features of NC machine tools

Machine machines can be broadly divided into general -purpose machine tools and NC machine tools.General -purpose machine tools manipulate various handles to create one product and parts.Skills are required for operation.In addition to the sound and vibration during processing, the appropriateness of the processing conditions is determined based on the color, shape, and processing surface of the caught chopping, and the processing is performed in response to it.On the other hand, NC machine tools are machine tools that perform a series of movements related to processing by program (NC program).When the processing is started, the processing is automatically performed until the end, so the program must include the optimal processing information.

Let's take a look at the characteristics of general -purpose machine tools and NC machine tools.

1)汎用工作機械

...

>>第2回 第1章の続きを読む(PDFダウンロード)

2.Configuration of NC machine tools

NC machine tools are composed of NC control boards and machinery.The composition of the machine itself varies depending on the type of NC machine tool.Here, we will look at the composition of NC lathes and machining centers, which are typical NC machine tools.

The configuration of the NC lathe is as follows.

1)主軸台

It has a motor and a transmission that rotates the main axis in the spindle that rotates the work.The main axis usually comes with a chuck to attach the work.

図1:主軸台The typical chucks are as follows.

・四つ爪単動チャック(インデペンデントチャック)

...

>>第2回 第2章の続きを読む(PDFダウンロード)

3.Type of NC machine tools

There are many types of NC machine tools, such as cutting, grinding, discharge, and laser processing.Here are some of the types.

・NC 旋盤

工作物を回転させて、バイトと呼ばれる工具により切削加工を行う工作機械で、外径・内径旋削や穴加工、溝加工、ねじ加工などを行うことができます。工具切れ刃と工作物が離れずに加工が行われる連続切削となるため、無人加工を行う上では切りくず処理が重要となります。大きな特徴としては、...

>>第2回 第3章の続きを読む(PDFダウンロード)

3rd: NC Program

The NC machine tool creates an NC program that incorporates the information required for processing and performs automatic processing by executing the program.The method of creating a program uses software such as manual programming andCAD/CAM system.I will explain the NC program.

1.NC programming method

In order to process products and parts drawn on the mechanical drawing with NC machine tools, it is necessary to put the information on mechanical operation in the NC program in detail and accurate NC program in the words (NC languages) that can be understood by the NC.。Creating an NC program is called NC programming.As shown in Fig. 1, the programming method of NC processing can be broadly divided into two.

一つはマニュアルプログラミング方式で、機械図面から加工内容を読みとり、加工工程や使用工具、加工条件、取り付け具などを決定します。そして、電卓などにより、...

>>第3回 第1章の続きを読む(PDFダウンロード)

2.Manual programming

Figure 2 shows the flow from the machine drawing to the product.In order to create an NC program in the manual, it is necessary to have the specifications of NC machine tools, tools, tools, knowledge of processing conditions, and the ability to study processing processes.In addition to programming, it is necessary to understand the meaning of various NC code and the command method, as well as coordinate systems, program configurations, and minimum set units.

図2:機械図面から製品加工までの流れ1)NCプログラム作成時の検討事項

...

>>第3回 第2章の続きを読む(PDFダウンロード)

3.CAD/CAM

CAD (Computer Aided Design) is a software that is translated as a design with computer support and creates a two -dimensional drawing or performs three -dimensional modeling.On the other hand, CAM (Computer Aided Manufacturing) is a software that is translated as a computer -supported manufacturing and creates an NC program based on CAD data.It consists of a main processor and a post processor.

まず、メインプロセッサで、...

>>第3回 第3章の続きを読む(PDFダウンロード)

4th: NC code

The NC code is a command code that determines the operation of NC machine tools used in the NC program.Specifies the rotation, movement, movement speed, etc. of tools and tables in the NC code.This section describes the meaning and specific command method of G code, M code, and other code.These codes are specialized in the types of NC machine tools and manufacturers.Here, each manufacturer is common, and we will focus on the code used in the NC lathe and machineing center.

1.Absolute method and inclaimental method

There are two ways to order tools: Absolute and Incertic Matters.The Absolute method (absolute price command system) is directly instructed by coordinates from the work coordinate system, regardless of the current position of the tool.The inclemental method (incremental price command order) is directed by the distance and direction from the current point of the tool to the point (target point).

図1は、XY平面図において、...

>>第4回 第1章の続きを読む(PDFダウンロード)

2.Various functions

1)O:プログラム番号

Program numbers are numbers for identifying specific programs.After the address o, give the number within 4 digits and attach it to the top of the program.It has a number that can be protected (protected) depending on the manufacturer and models, such as the O8000s and the O9000 series, and is used in macro programs and maintenance programs that are usually not to be edited.Depending on the manufacturer, some models can be managed by file name instead of program numbers.

また、...

>>第4回 第2章の続きを読む(PDFダウンロード)

3.G code

Gコードは準備機能と呼ばれ、指令されたブロックにおける工具の動きやモードを指定します。アドレスGのあとにコード化された2桁の数値で指令します。表2はNC旋盤、表3はマシニングセンタのGコード一覧です。表以外にも、...

>>第4回 第3章の続きを読む(PDFダウンロード)

4.M code

M コードは補助機能と呼ばれ、主軸の正転・逆転・停止やクーラントのON・OFFなど、機械側の個々の機能を制御するコードです。アドレスMのあとにコード化された2桁の数値で指令します。表4にMコード一覧(NC旋盤・マシニングセンタ共通)を示します。表以外にも、...

>>第4回 第4章の続きを読む(PDFダウンロード)

5th: NC processing setup work

The NC processing setup work includes the installation of tools and work, and the setting of the work coordinate system, the setting of various corrections, and the transfer (input) of the program.Since the operation of the machine is performed, it is necessary to do it quickly and accurately.Here, we will focus on the setup of NC lathes and machineing centers.

1.Flow from drawing to product

図1は機械図面から製品加工までの流れを示しています。NC工作機械の段取り作業は、工具番号や補正番号などの工具情報、工作物の大きさや加工形状、ワーク座標系設定に関する情報があれば、...

>>第5回 第1章の続きを読む(PDFダウンロード)

2.Installation of tools and works

1)工具の取り付け

Attach the tool selected according to the material and processing shape of the work to the NC machine tool.See the tool number of the toollist created during the NC programming and attach it.

NC旋盤について説明します。図2に示すような外径バイトや内径バイトを刃物台に取り付けます。外径バイトはNC旋盤の仕様によりシャンク(柄)の寸法が20mm角や25mm角などがあります。シャンク仕様にあわせたバイトを取り付けると、...

>>第5回 第2章の続きを読む(PDFダウンロード)

3.Settings of the work coordinate system

The idea is to set the amount and direction of shifting from the mechanical coordinate system.Therefore, if the work coordinate system is not set, the mechanical coordinates of the mechanical coordinate system = the work coordinate system.

In the setting of the NC lathe's work coordinate system, the X -axial direction (diameter direction) is the origin of rotation.As shown in FIG. 8, the Z -axial direction (longitudinal direction) varies depending on the user, such as P1 (finished end face), P2 (raw nail end), P3 (chuck end).Many are set to P1.If you set to P1, the Z -axial command value of the NC program will generally be a change, but if you set it to P2 and P3, all will be the right value command.

図8:Z軸方向の原点位置ワーク座標系原点の設定には、工具形状補正を使用する方法とGコードによる座標系設定があります。ここでは...

>>第5回 第3章の続きを読む(PDFダウンロード)

4.Set of various correction values

NC旋盤では自動刃先半径補正に関する補正値を入力します。機械側はこの値を使ってバイトの補正経路を自動計算します。マシニングセンタでは工具長補正および工具径補正に関する補正値を入力します。工具長補正に必要な工具の長さは、...

>>第5回 第4章の続きを読む(PDFダウンロード)

5.Program transfer

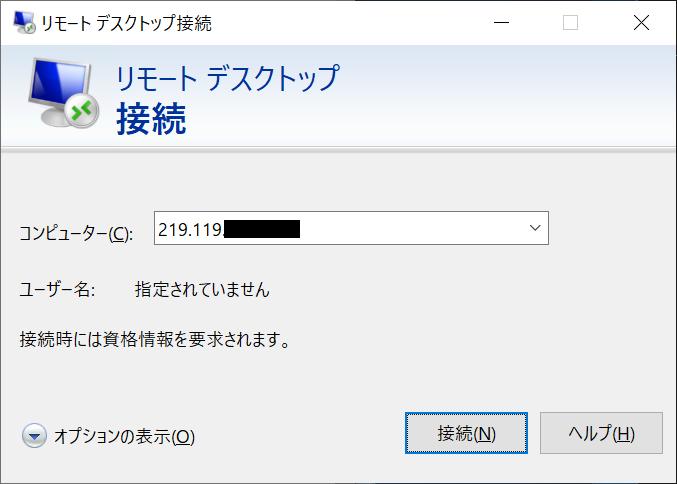

The method of remembering the NC program to the memory of the NC machine tool can be broadly divided into two.One is to enter directly from the NC operation board (MDI: Manual Data Input), and the other is a text file and transferred by software.Recent NC machine tools have memory cards and USB memory ports, so they can be transferred relatively easily.

パソコンとNC工作機械をRS-232CやRS-422、光ケーブルなどのケーブルで接続して転送する場合、使用ケーブルにより転送速度が異なります。また、...

>>第5回 第5章の続きを読む(PDFダウンロード)

6th: Points from program check to continuous operation

Before entering continuous operation, run the NC program to see if there are any errors in the content of the program and the correction value such as the work coordinate system.In addition, we will also check whether the product and parts that meet the request of the machine drawing can be processed by performing trial processing, and whether the optimal conditions are set.I will explain the points from program check to continuous operation.

1.Program check

If there is an error in the created NC program or the set correction value, the tool may interfere with the work, jigs, tables, etc. and may damage the tools and machinery.Therefore, execute the program to check if there is any mistake.Checking methods include checking by drawing function and air cut (empty operation).

Explains three switches: mode selection of machine tools, NC function selection, and override to use when performing program checks.Figure 1 shows the mode selection switch.This is the first switch to select what you want to do when operating an NC machine tool.Here, only the switches related to autonomous driving and handle mode are explained.

図1:モード選択スイッチ・メモリ

...

>>第6回 第1章の続きを読む(PDFダウンロード)

2.Trial processing and evaluation

After the program check, try the first one.Here, it is necessary to judge the suitability of the processing conditions.If you have trouble after entering continuous operation, time and cost loss will be large.

NC machine tools are covered with a cover, and many of them are processed with coolant, so you can hardly check the cuts and sparks during processing.Therefore, it is necessary to judge the sound and vibration during processing, the state of the edge of the blade after processing, the dimensions accuracy of the processed product, and the surface roughness.We may check the main shaft load road meter.

NCプログラムの各工程間にM01を入れておき、オプショナルストップスイッチを有効にしておくと、それぞれの工程後に加工状態が確認できます。また、...

>>第6回 第2章の続きを読む(PDFダウンロード)

3.Continuous operation

Trial processing will be performed, and if there is no mistake in the NC program, processing conditions, and various correction values, it will enter continuous operation.If the tools are worn for a long time with the same tool, regular dimensions are required so that defective products do not occur.

機械図面に指示された寸法公差を外れる前に摩耗補正で調整、あるいは工具を交換します。工具寿命管理については、...

>>第6回 第3章の続きを読む(PDFダウンロード)

4.Equipment to produce accuracy

In order to stabilize the processing accuracy of products and parts, the accuracy (static accuracy and dynamic accuracy) of machine tools must be high and must be stable.It also requires rigidity that does not deform due to the resistance at the time of processing.Even if the machine tool meets these, the processing accuracy may not be obtained depending on how it is used.The environment for installing a machine tool is one factor.If the foundation of the installation location is thin, the posture of the machine tool may change due to land subsidence.If there is a press machine nearby, vibration may affect the processing accuracy.Even if the outlet of the air conditioning equipment is nearby, the posture may change.

また、工作機械の主軸や各移動軸は...

>>第6回 第4章の続きを読む(PDFダウンロード)

![Lenovo's 8.8 inch one-handed tab "Legion Y700" full specs released! [Is the price in the 40,000 yen range?]](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/207e1be231154e91f34c85b4b1d2126c_0.jpeg)

![EVsmart blog Toyota's electric car "bZ4X" that makes you feel comfortable with electric cars and quick chargers / No% display of battery level [Editorial department] Popular articles Recent posts Category](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/752542064665dc2bd7addbc87a655694_0.jpeg)