Japan's first cloud precut service (*)

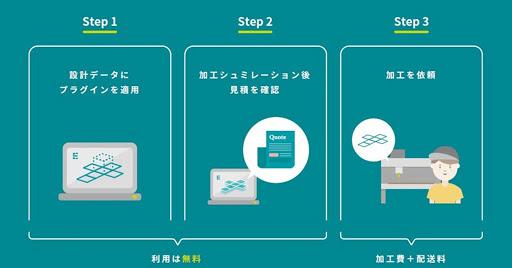

VUILD Co., Ltd. VUILD Co., Ltd. (VUILD, hereafter VUILD) today launched Japan's first cloud precut service "EMARF 3.0 ( Emmafu 3.0)" has been released. "EMARF 3.0" is plug-in software that extends the functions of CAD (Computer Aided Design). You can submit online CAD data for wooden architectural parts that previously required specialized knowledge or were given up due to constraints such as cost and delivery, and output them as if you had your own workshop. In the construction and design industry, most meetings, including drawing creation, have been held face-to-face (offline). However, as one of the measures to prevent the spread of the new coronavirus (COVID-19), the industry is also required to shift to a remote-based work style as soon as possible. In such an environment, "EMARF 3.0" does not require any offline meetings until now, and provides a mechanism that allows everything from design to processing requests to be completed online, realizing online manufacturing. increase. By using EMARF 3.0, designers can automatically generate processing data, estimate processing costs and material costs, and instantly calculate online from the data drawn with the CAD software they usually use. After agreeing on the details of the estimate, the processing data is sent to builders and lumber mills nationwide that have CNC routers, and processing begins. As a result, the architectural designer can grasp the feasibility and budget at the time of design, and since there is less design rework, the time can be significantly reduced, allowing the designer to concentrate on the original design work. Also, since CAD is directly connected to CNC routers and other digital processing machines via EMARF 3.0, there is little gap between the image at the time of design and the actual building, making it possible to realize what you envisioned. became. In addition, because digital processing is performed by machines, even complex designs can be realized at relatively low cost. * Pre-cutting: Cutting and processing wooden fittings, interiors, furniture, fixtures, structural parts, etc. at the factory in advance before construction on siteThis press release contains information for media personnel.

If you register as a media user, you can view various special information such as contact information for company representatives and information on events and press conferences. *The content varies depending on the press release.

![Lenovo's 8.8 inch one-handed tab "Legion Y700" full specs released! [Is the price in the 40,000 yen range?]](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/207e1be231154e91f34c85b4b1d2126c_0.jpeg)

![EVsmart blog Toyota's electric car "bZ4X" that makes you feel comfortable with electric cars and quick chargers / No% display of battery level [Editorial department] Popular articles Recent posts Category](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/752542064665dc2bd7addbc87a655694_0.jpeg)